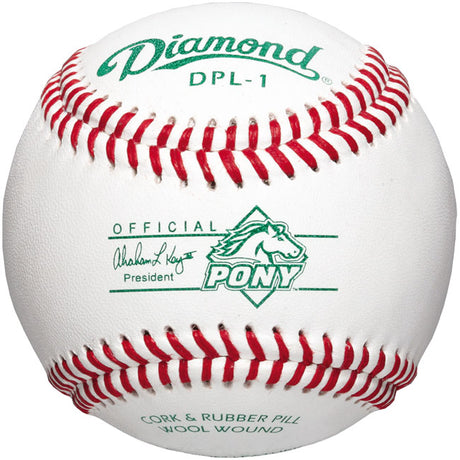

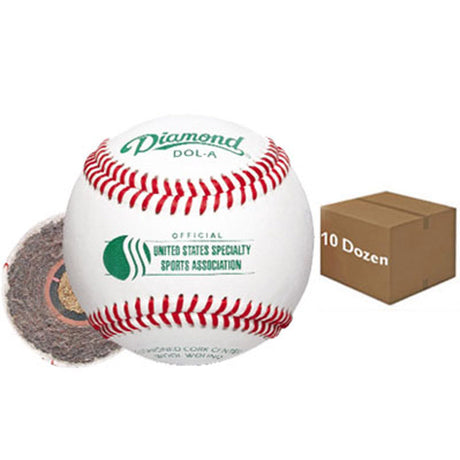

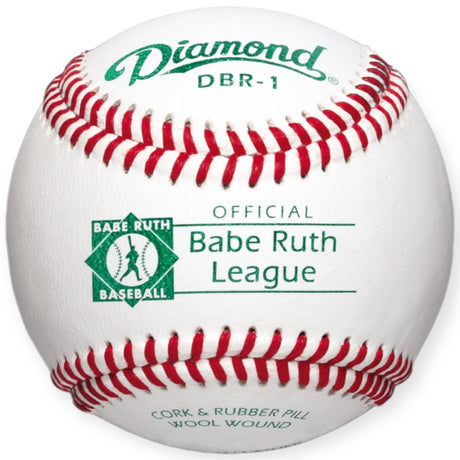

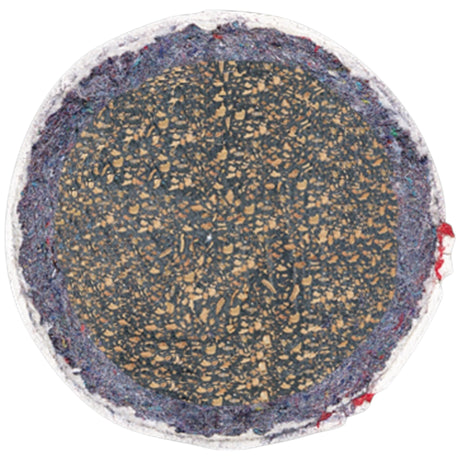

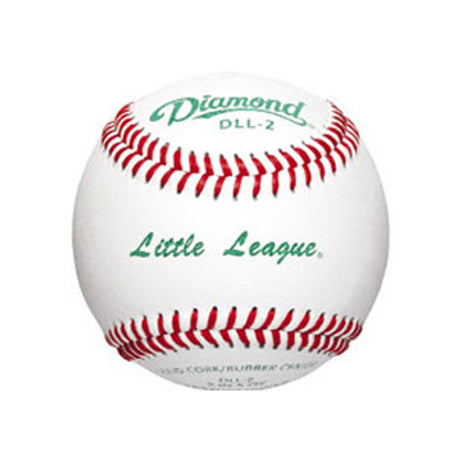

Diamond

Diamond Blemished DOL-1 Official League Practice Baseball Dozen

$4799$6999Unit price /UnavailableDiamond

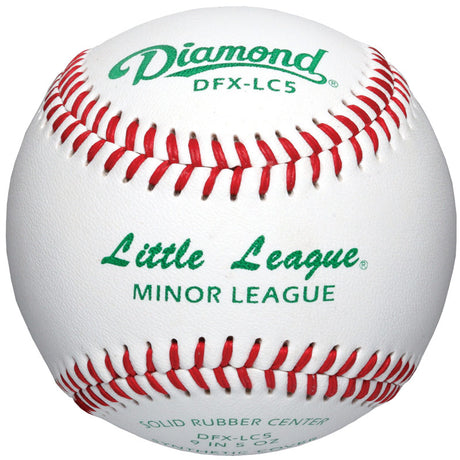

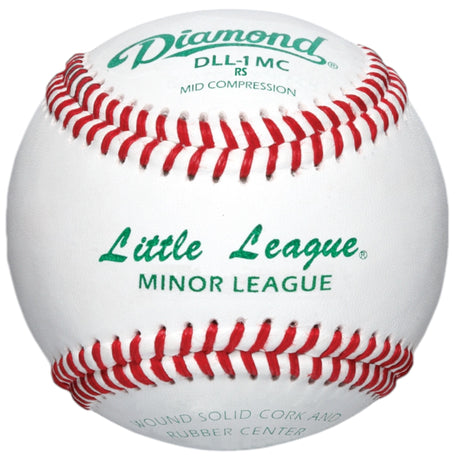

Diamond DFX-LC5 LL Little League Mid Compression Game Baseball Dozen

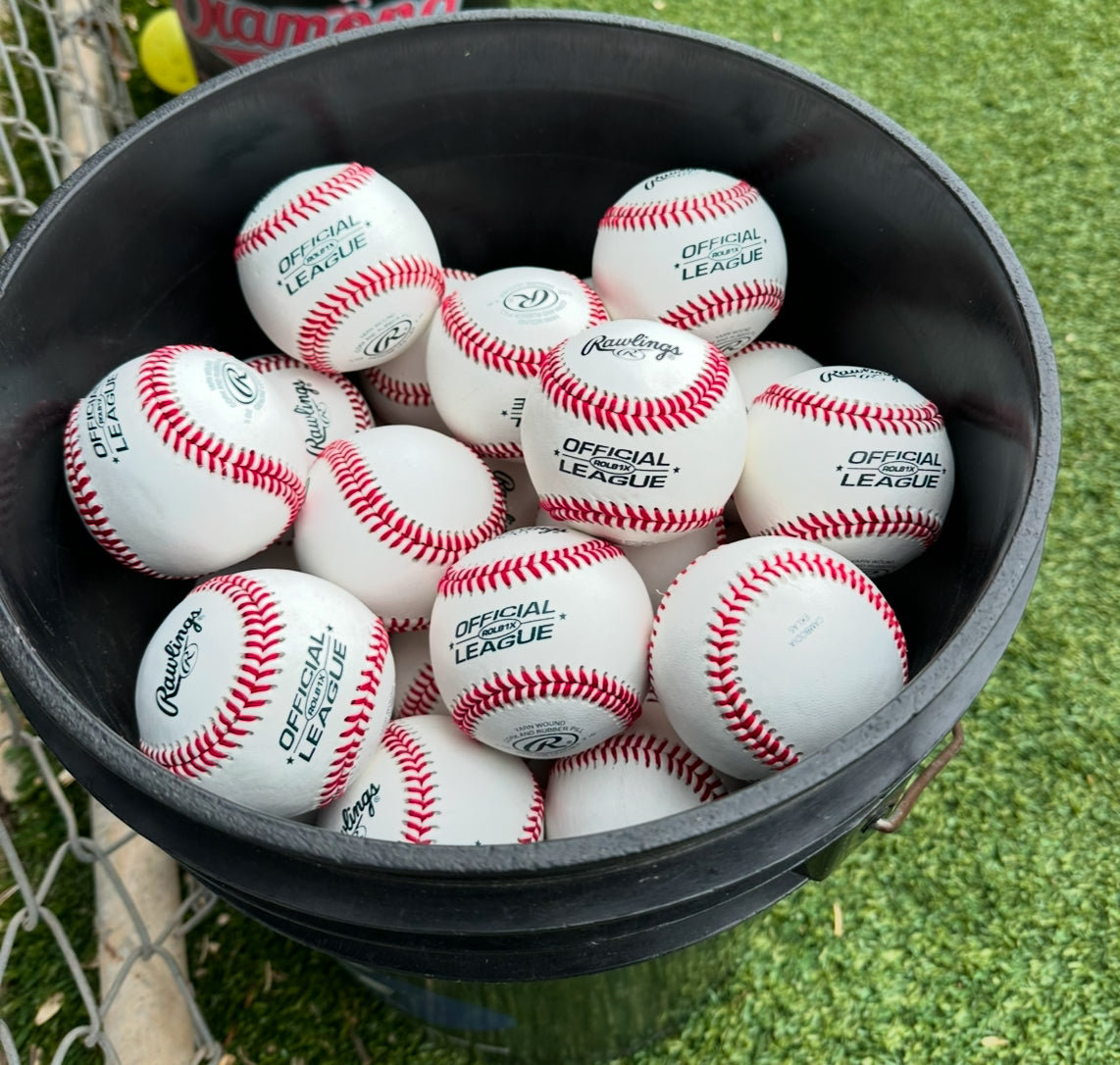

$4997Unit price /UnavailableRawlings

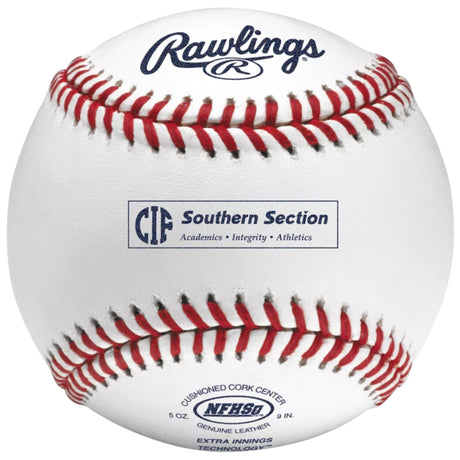

Rawlings CIF Southern Section Game Baseballs RCIFSS - Dozen

$6999$10999Unit price /UnavailableDiamond

Diamond DFX-9YL Flexi Ball/Soft Touch Batting Practice Baseball 10 Dozen

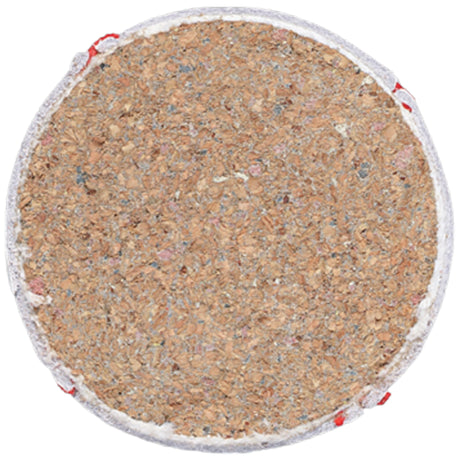

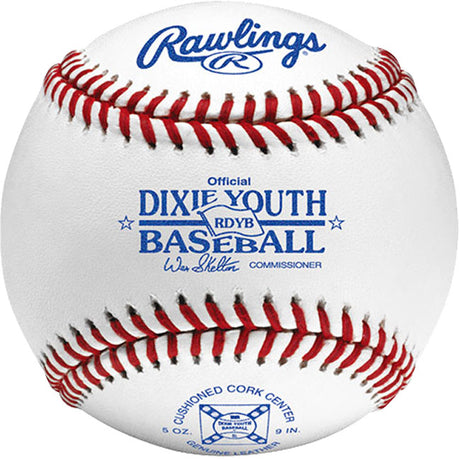

$58597Unit price /UnavailableRawlings

Rawlings Dixie Youth League Baseball (Tournament Grade) RDYB (1 Dozen)

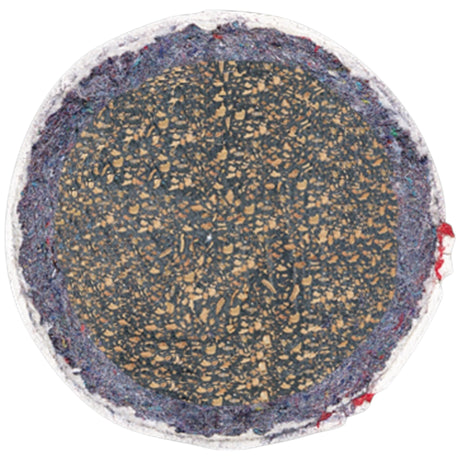

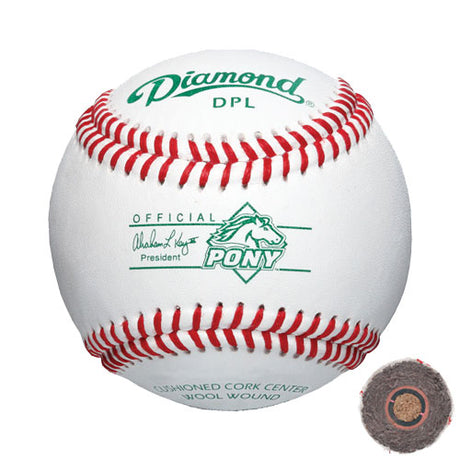

$6999Unit price /UnavailableDiamond

Diamond DMBP Pitching Machine Batting Practice Baseball (2 Dozen Pack)

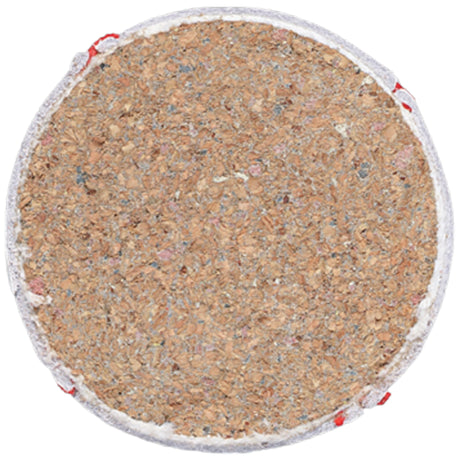

$17997Unit price /UnavailableDiamond

Diamond DMBP Pitching Machine Batting Practice Baseball (10 Dozen)

$78997Unit price /Unavailable